Categories

Double stack self-locking washers

Anti-loose gasket is also known as anti-loose gasket, self-locking gasket, self-locking gasket, DIN25201 anti-loose gasket, double self-locking anti-loose gasket, double stacked wedge anti-loose gasket, etc.The anti-loose gasket is composed of two gaskets of uniform specifications, each with radial convex surface on the outside and helical tooth surface on the inside.

- Description

-

Anti-loose gasket is also known as anti-loose gasket, self-locking gasket, self-locking gasket, DIN25201 anti-loose gasket, double self-locking anti-loose gasket, double stacked wedge anti-loose gasket, etc.The anti-loose gasket is composed of two gaskets of uniform specifications, each with radial convex surface on the outside and helical tooth surface on the inside.

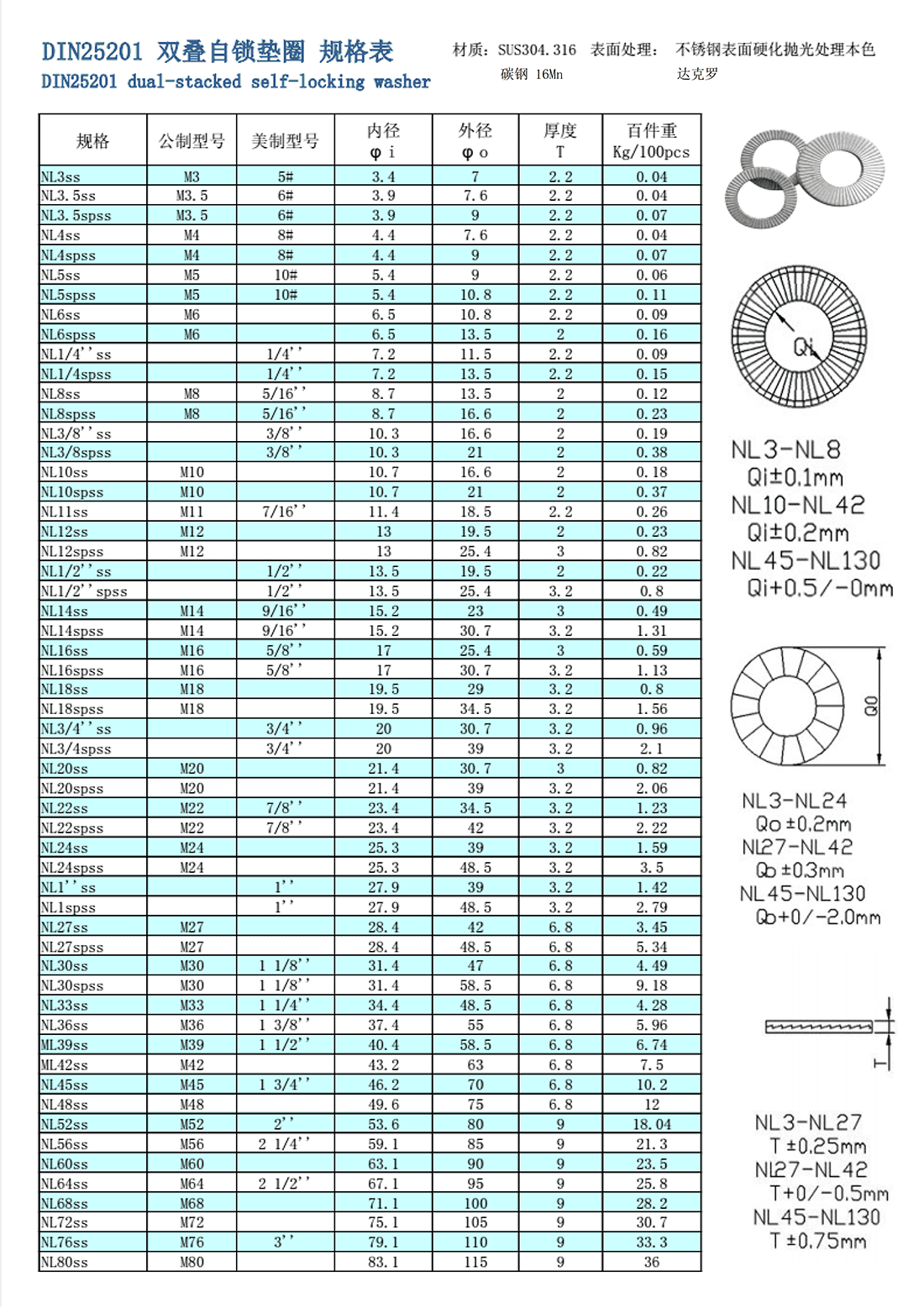

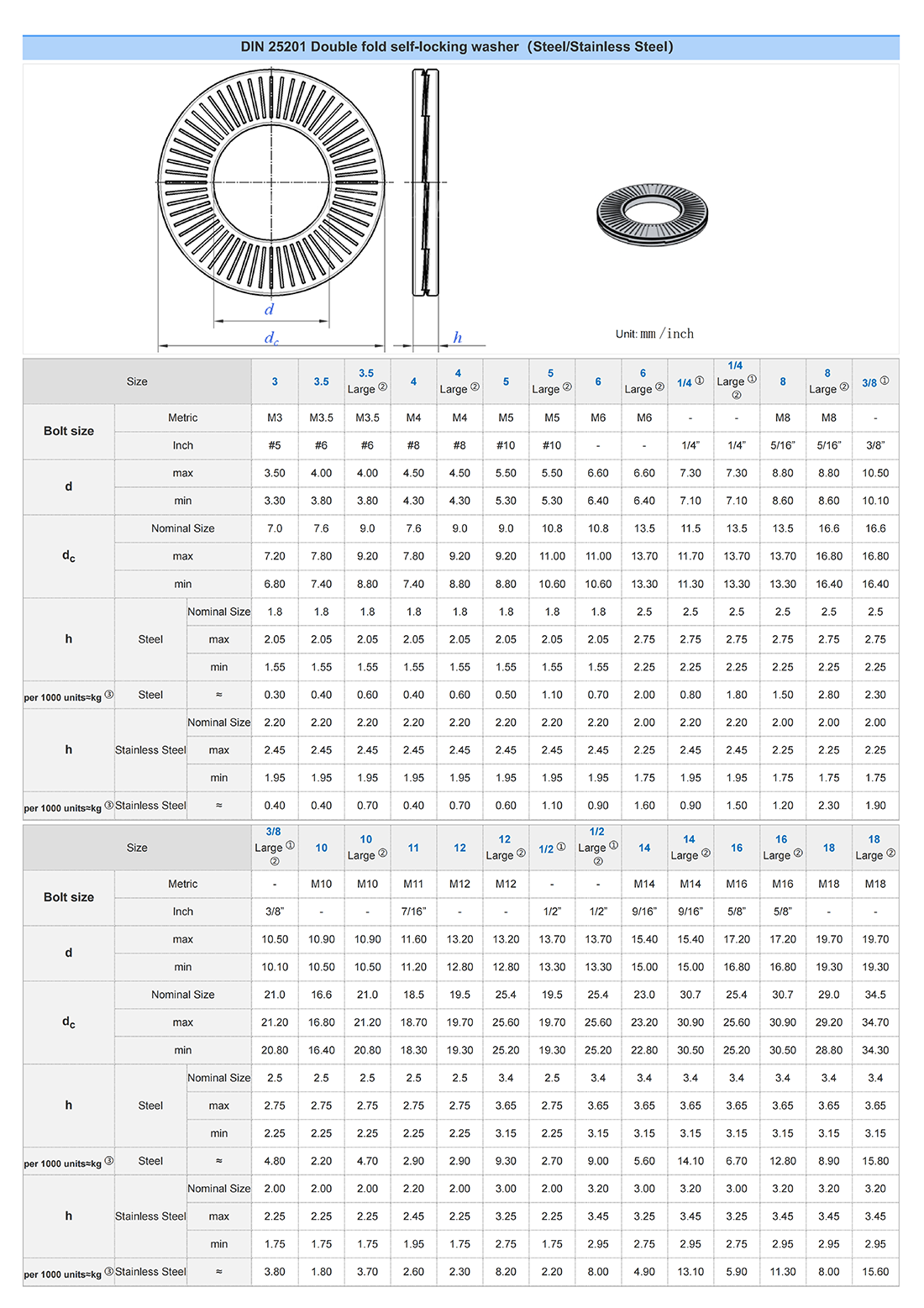

Name Double fold self-locking washer Check washer Lock Washer NORDLOCK Double stack self locking washer Standard DIN 25201 Size M3~M42 Material Steel/Stainless Steel Surface Carbon steel to do dacro treatment, stainless steel surface hardening polishing treatment Description Anti-loose gasket is also known as anti-loose gasket, self-locking gasket, self-locking gasket, DIN25201 anti-loose gasket, double self-locking anti-loose gasket, double stacked wedge anti-loose gasket, etc.

The anti-loose gasket is composed of two gaskets of uniform specifications, each with radial convex surface on the outside and helical tooth surface on the inside.Construction operation technology The anti-loose gasket is easy to install.

1. Just place the inner helical tooth surface of the two spacers opposite to each other and place them between the nut and the connecting material;

2. After the nut is tightened, the outer radial convex surface of the anti-loosening washer is occluding with the contact surface at both ends, and the Angle of the slope bevel of the inner helical tooth surface of the washer is greater than the screw thread Angle of the bolt;

3. When the bolt is stretched due to mechanical vibration, the nut will rotate and loosen accordingly. Because the friction force of the outer radial convex surface of the anti-loosening washer is greater than that of the inner helical tooth surface. In this state, only the relative dislocation between the medial helical teeth is allowed, and then a certain lifting tension is generated.

4. When the bolt shrinks, the helical surface of the washer will bring the nut back to its original position. So as to achieve 100% anti-loose and tight effect;

5. Gaskets are suitable for flat and smooth surfaces;

6. If the connection material is non-metallic, a metal plate can be fixed on the connection material, so that you can use anti-loose gasket;

7. Do not use a torque wrench when installing a lockproof washer;

8. Optional use of pneumatic tools when installing or removing lock gaskets.Scope of application The conventional gasket is a single piece of spacer work independently, this gasket mainly relies on friction to achieve loosen effect.

The new gasket is composed of two pieces, its unique embedded structure has changed the traditional gasket mainly through friction to achieve the way to prevent loose, but the international most advanced anti-loose technology, using the tension between two gaskets to achieve the double effect of anti-loose and tight.

Keywords:

Keywords:- Double stack self-locking washers

Partner Brands

Send Inquiry

NOTE: Please leave your email, our professional person will contact you asap!

Related Product

undefined

JUNCHUANG

Our Products

Contact Us

North of Xitantou Village, Linmingguan Town, Yongnian District, Handan City, Hebei Province, China.

Follow Us

Hevel

Amiee Wang