Categories

Pan head Phillips screw

Cross pan head screw material is divided into iron, that is, carbon steel, also divided into stainless steel. There are three kinds of carbon steel, low carbon steel, medium carbon steel and high carbon steel. Stainless steel has stainless steel SUS201 and stainless steel SUS304, stainless steel SUS316, stainless steel SUS404 and so on.

- Description

-

Cross pan head screw material is divided into iron, that is, carbon steel, also divided into stainless steel. There are three kinds of carbon steel, low carbon steel, medium carbon steel and high carbon steel. Stainless steel has stainless steel SUS201 and stainless steel SUS304, stainless steel SUS316, stainless steel SUS404 and so on.

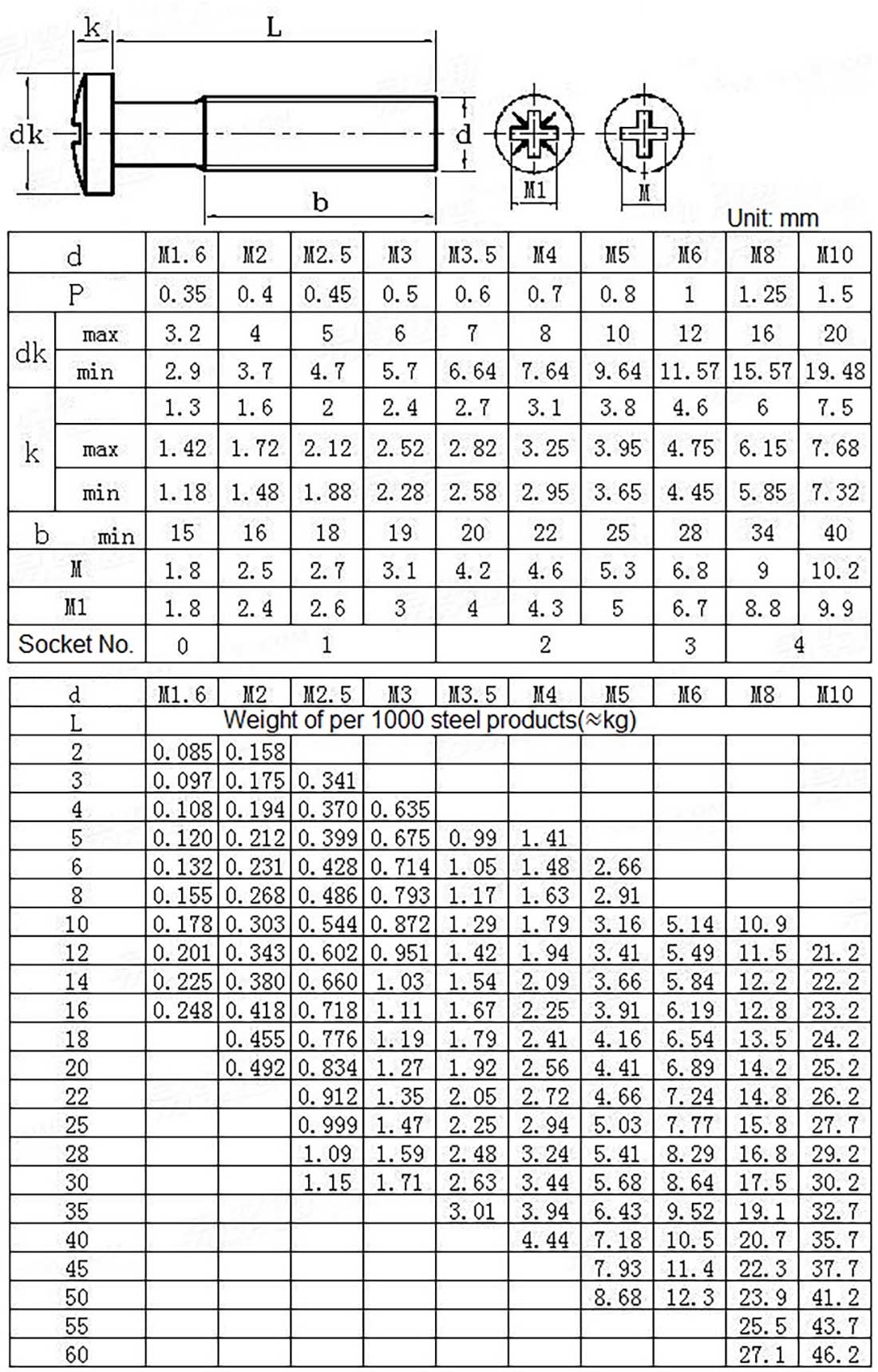

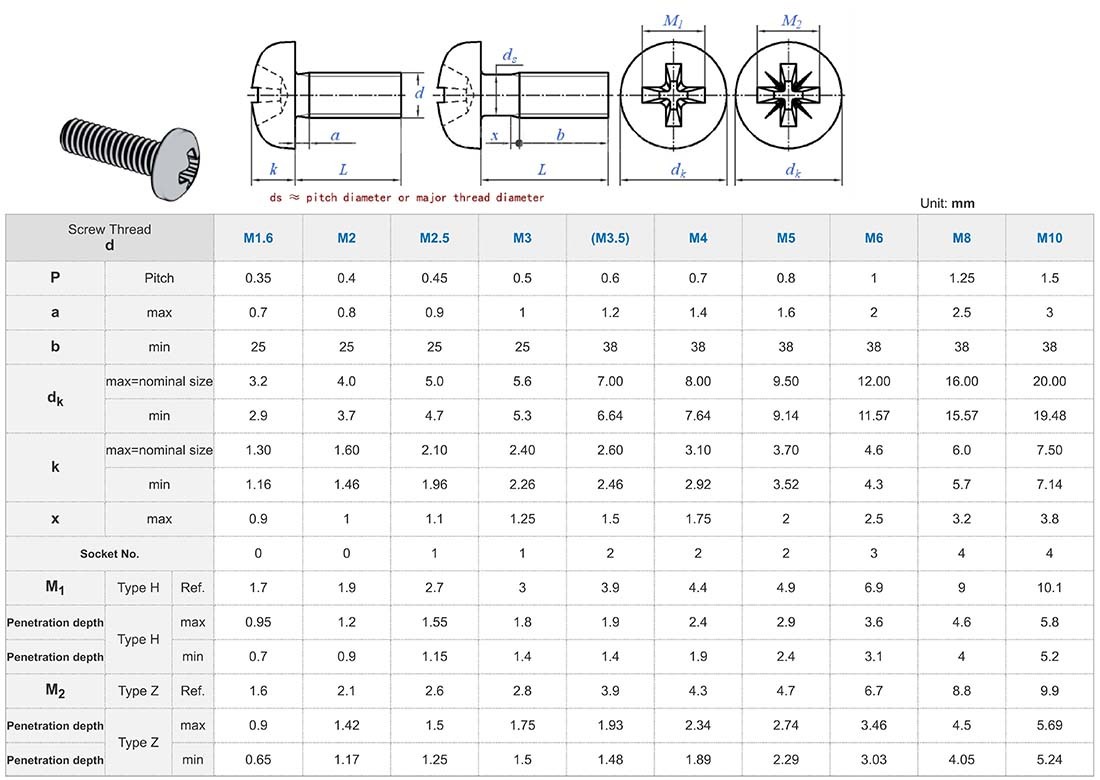

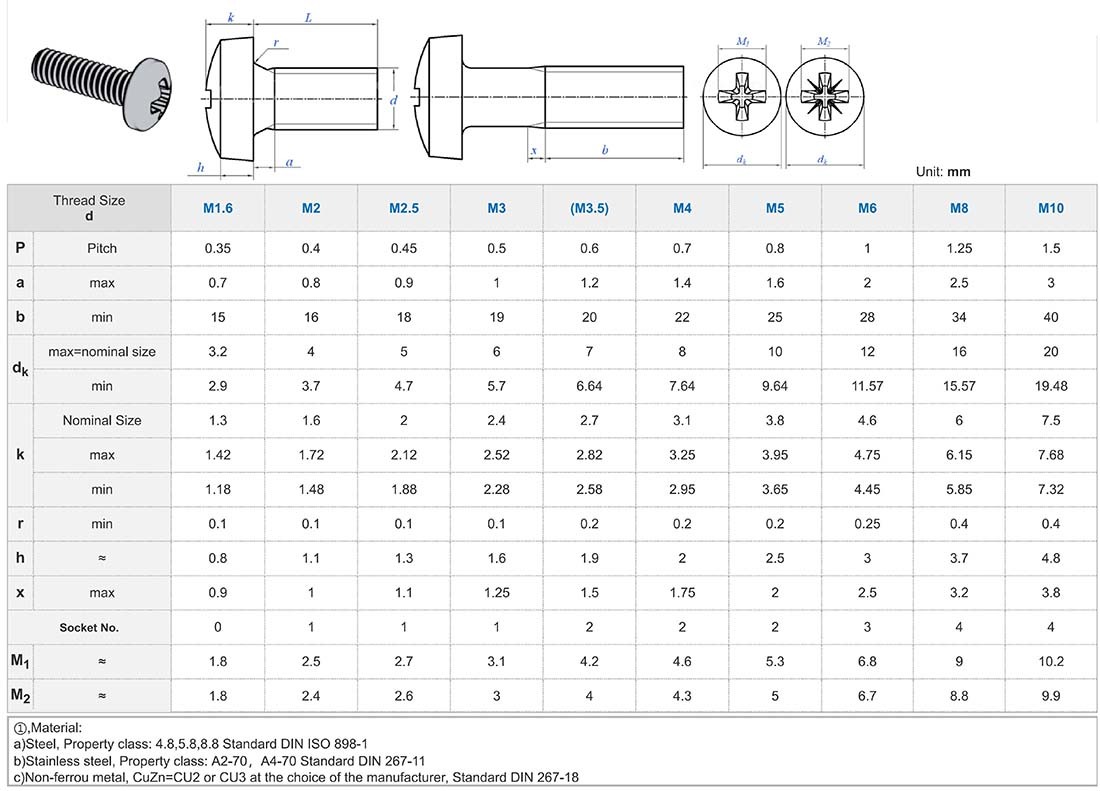

Name Pan head screws with cross recess Standard DIN 7985 ISO 7045 GB/T 818 Size M3~M8 Length 25mm~120mm Grade 4.8 5.8 6.8 8.8 Material Cross pan head screw material is divided into iron, that is, carbon steel, also divided into stainless steel. There are three kinds of carbon steel, low carbon steel, medium carbon steel and high carbon steel. Stainless steel has stainless steel SUS201 and stainless steel SUS304, stainless steel SUS316, stainless steel SUS404 and so on. Surface Cross pan head screw plating color. Common electroplating, white nickel, black zinc, blue zinc, etc., environmental protection has environmental protection white zinc, environmental protection color zinc, environmental protection white nickel, environmental protection blue zinc, etc. Description Cross recessed pan head screw refers to cross recessed machine screw and is indicated by the letter PM. State specified thread specifications for M1.6-M10, performance grades 1.8, A-50, A2-70, CU2, CU3 and AL4, H and Z cross groove, product grade A cross groove pan head screws. Construction operation technology First, the thread diameter of the screw wire is tested, and the material of the screw is tested. Generally, the thread diameter of the screw is used to measure the size of the wire diameter, whether it is the same as the size used. After detecting these, it is the detection in the production process, starting from the screw head, determine the head size, head side, diagonal, cross groove depth, screw tolerance range and so on. These are all detected with calipers. Then is the detection of all aspects of dental rub, the main thing is that the dental thread can not pass through the stop gauge, screw thread can not pass through the gauge, stop. Finally, the problem of electroplating measurement. After electroplating is good, is it in line with the environmental requirements, can the salt spray required time. Tools are environmental testing machines, salt spray testing machines. Scope of application Mostly used for the connection of smaller parts. It has pan head screws, cylindrical head screws, half countersunk head screws and countersunk head screws. The screw head strength of the pan head screw and the cylindrical head screw is higher, and the bill screw is connected on the common parts. The head of the semi-countersunk head screw is arc-shaped, and its top is slightly exposed after installation, and beautiful and smooth, generally used in instruments or precision machinery; Countersunk head screws are used where the head is not allowed to be exposed.

Cross groove common screw groove strength is high, not easy to screw bald, appearance is more beautiful. When in use, it must be loaded and unloaded with the matching cruciform screw.

Keywords:

Keywords:- Pan head Phillips screw

Partner Brands

Send Inquiry

NOTE: Please leave your email, our professional person will contact you asap!

Related Product

undefined

JUNCHUANG

Our Products

Contact Us

North of Xitantou Village, Linmingguan Town, Yongnian District, Handan City, Hebei Province, China.

Follow Us

Hevel

Amiee Wang