Categories

Countersunk cross self-tapping

Self-tapping screw surface treatment: Most self-tapping screws are coated with zinc coating or zinc phosphate coating.

- Description

-

Self-tapping screw surface treatment: Most self-tapping screws are coated with zinc coating or zinc phosphate coating.

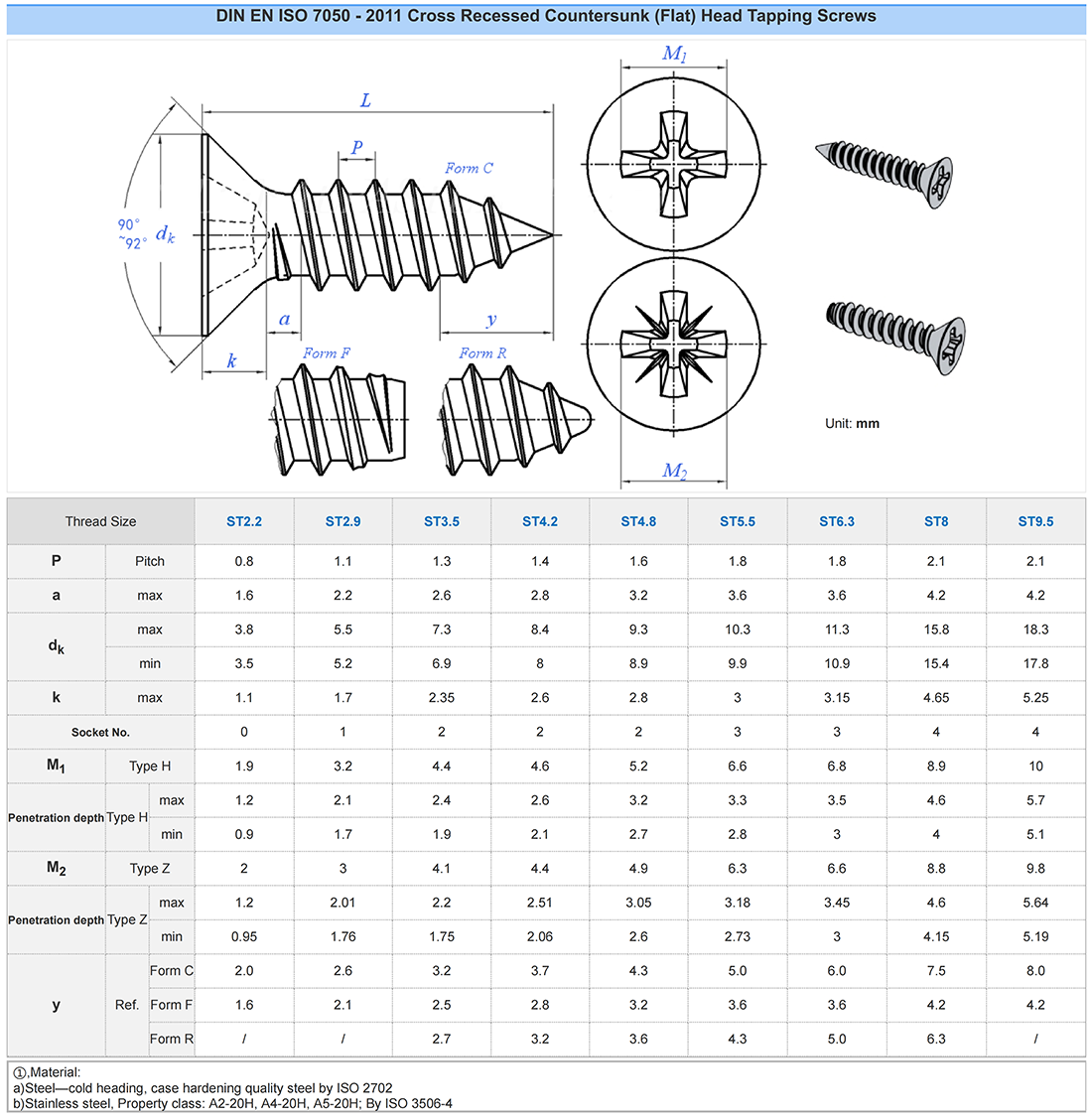

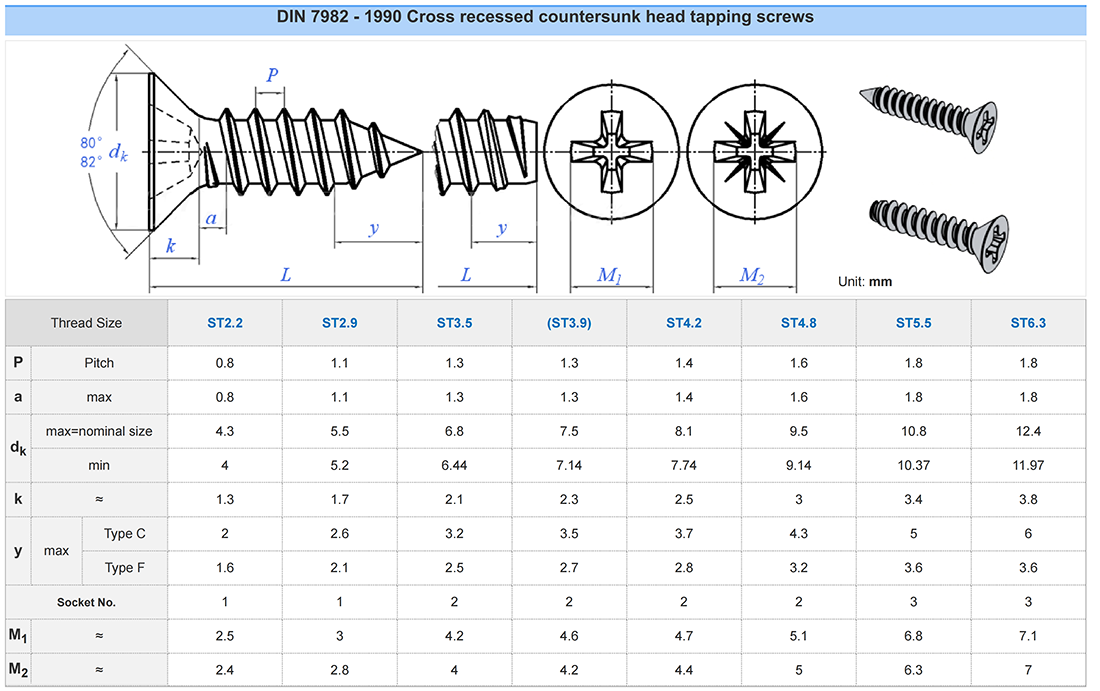

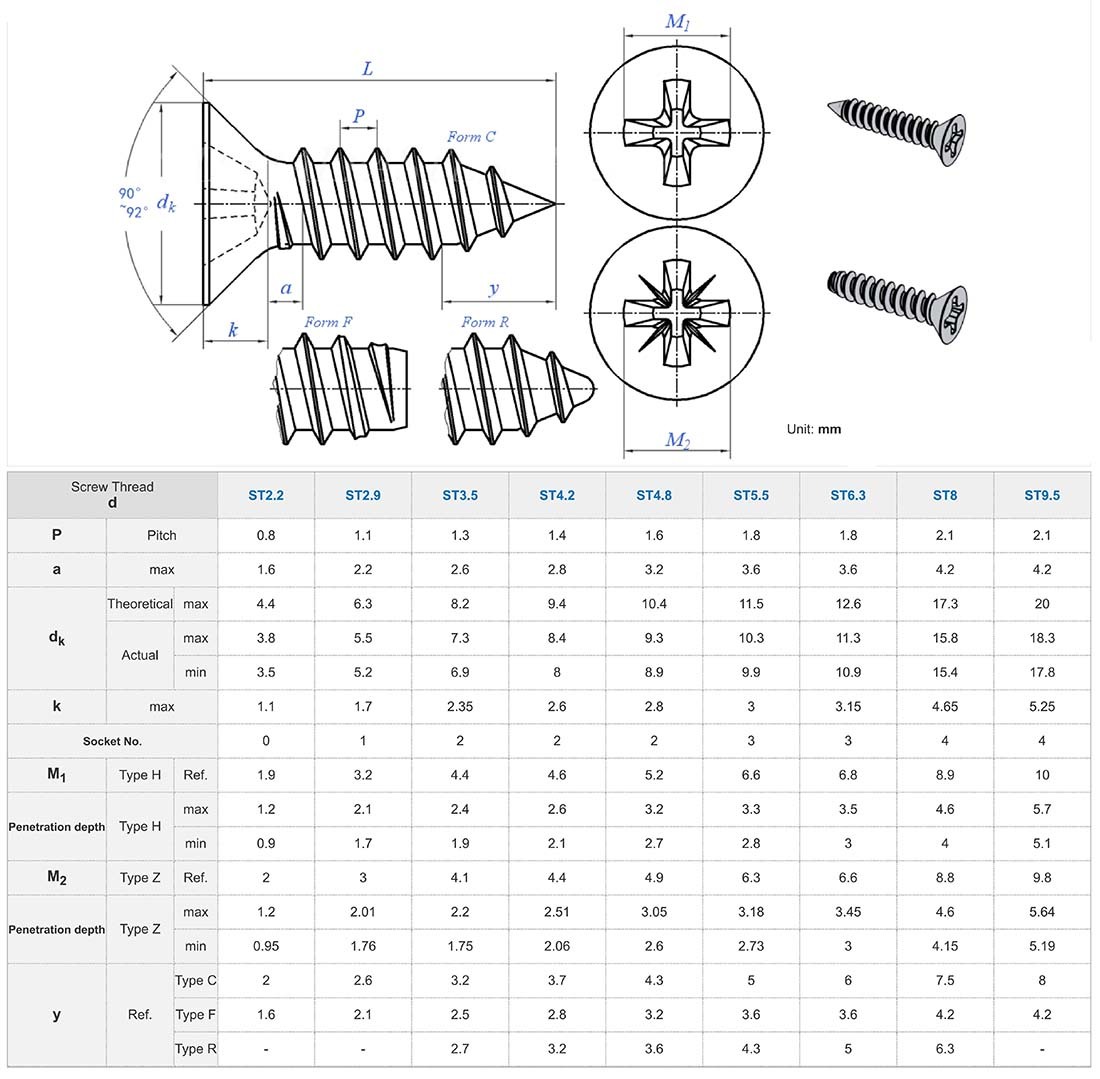

Name Cross countersunk head self tapping screw Cross Recessed Countersunk (Flat) Head Tapping Screws Cross Recessed Countersunk Head Tapping Screws Standard DIN 7982 DIN EN ISO 7050 GB _T 846 Size M2.9~M6.3 Length 25mm~120mm Grade 4.8 5.8 6.8 8.8 Material Although there are many types of self-tapping screws, they all have the following main characteristics:

(1) are generally made of carburizing steel (accounting for 99% of the total product). It can also be made of stainless steel or non-ferrous metals.

(2) The product must undergo heat treatment. Carbon steel tapping screws must be carburized, stainless steel tapping screws must be solution hardening treatment. In order to make the tapping screw to meet the standard requirements of mechanical properties and performance.

(3) The product surface hardness is high, the core toughness is good. That is, "soft inside, tough outside". This is a major feature of tapping screw performance requirements. Such as low surface hardness, screw into the matrix; If the core toughness is poor, a twist on the broken, can not be used. Therefore, "soft inside and rigid outside" is a self-tapping screw to meet the requirements of performance.

(4) The surface of products all need surface protection treatment, usually electroplating treatment. The surface of some products needs phosphate treatment (phosphating). Such as: wall tapping screws for phosphating.

(5) Production by cold heading technology. It is recommended to use high speed cold header, high speed wire rolling machine or high speed planetary wire rolling machine to ensure product quality. This production of self - tapping screw head molding good, high thread quality.Surface Self-tapping screw surface treatment: Most self-tapping screws are coated with zinc coating or zinc phosphate coating. Description Self-tapping screw definition refers to the self-tapping screw that does not need to be used with the nut. The tooth thread is self-tapping type and the tail tip. When the triangle self extrusion screw is screwed into the hole of plastic metal material, it can form internal thread and form reliable locking thread connection in the hole by extrusion action. Construction operation technology Self - tapping screws from head to tail are composed of the head, the rod and the rod end of three parts. Each self-tapping screw has four main elements: the shape of the head, the way of pulling, the type of thread, and the type of the end.

Head shapes. - Heads come in all shapes. There are round head (half round head), flat head, round head flange (with pad), flat head flange (with pad), pan head, pan head flange (with pad), countersunk head, half countersunk head, cylinder head, spherical cylinder head, horn head, hexagonal head, hexagonal flange head, hexagonal flange head (with pad) and so on.

The way to twist. - There are many ways to twist. External pulling: hexagonal, hexagonal flange, hexagonal flange, hexagonal flower shape, etc.; Internal pull screw: word groove, cross groove H (Phillips), cross groove Z (Pozidriv), cross groove F (Frearson), square groove (Scrulox), compound groove, internal spline, hexagon flower shape (club groove), inner triangle, hexagon socket, 12 Angle, clutch groove, six blade groove, high torque cross groove and so on .

Thread Types - There are many thread types. There are self tapping threads (wide tooth threads), machine threads, dry wall screw threads, fiber board screw threads, and some other special threads. In addition, the thread can be divided into single lead (single head), double lead (double head), multi lead (long head) and high and low teeth double head thread.

End type - End type is mainly sawn end, flat end. But according to the use function can be machined with cutting function of groove, groove, notch or similar to the shape of the drill, etc. In some standards, the same sawn end or flat end, also have different forms.

From the above introduction can be seen: self tapping screw head shape, pull screw way, thread type and rod end type, etc., there are a variety of changes. They can be combined with each other to release a large number of different products belonging to the category of self-tapping screws.Scope of application Self-tapping screw is a kind of screw with drill bit, through the special power tool construction, drilling, tapping, fixing, locking, tightening to complete. Self-tapping screws are mainly used for the connection and fixation of some thin plates, such as the connection of color steel plate and color steel plate, color steel plate and purlin, wall beam connection, the penetration capacity is generally not more than 6mm, the maximum is not more than 12mm. Self-tapping screws are often exposed to the outdoors and have strong corrosion resistance; The rubber sealing ring can ensure that the screw does not seepage and has good corrosion resistance.

Keywords:

Keywords:- Countersunk cross self-tapping

Partner Brands

Send Inquiry

NOTE: Please leave your email, our professional person will contact you asap!

Related Product

undefined

JUNCHUANG

Our Products

Contact Us

North of Xitantou Village, Linmingguan Town, Yongnian District, Handan City, Hebei Province, China.

Follow Us

Hevel

Amiee Wang